At a Glance

- FY20 Implementation Partner activities included the launch of new ISS capabilities as well as additional milestones and firsts for ISS R&D.

- CASIS introduced a new Pioneer Allocation model that will provide Commercial Service Providers with more reliable access to the ISS National Lab as they mature their business models and expand their customer base.

- In recognition of the 20th anniversary of continuous human habitation on the ISS, CASIS invited Implementation Partners to contribute perspectives and insights about what the future may hold for their companies and the space industry—showcased in an online essay series.

- Several Implementation Partners put their expertise to work to assist industries amidst the global COVID-19 pandemic.

The ISS National Lab continues to evolve as an in-space business incubator, supporting service providers that give researchers the ability to leverage state-of-the-art laboratory tools in nearly every avenue of science and technology development. As manager of the ISS National Lab, CASIS is working alongside our Implementation Partners to test, validate, and make available hardware, facilities, and capabilities that drive new areas of inquiry, expand utilization of the ISS, maximize science return, and demonstrate successful LEO-based business models.

Examples of FY20 activities by the growing community of Implementation Partners and Commercial Service Providers (CSPs, the subset of Implementation Partners that manage permanent facilities on station) include the following:

- Nanoracks passed an important milestone in February with its 250th satellite deployment via the Nanoracks External Cygnus Program, the first program to have leveraged a Commercial Resupply Services vehicle for anything other than cargo resupply.

- The Bartolomeo platform from Airbus successfully launched in March and was installed in April; it will support use of LEO for applications including remote sensing, in-orbit manufacturing, and materials science.

- Made In Space celebrated the five-year anniversary of additive manufacturing in orbit and delivered its new Commercial Polymer Recycling Facility designed to convert plastic waste into feedstock for additive manufacturing, toward establishment of a regenerative materials cycle to reduce material waste in orbit without increasing the carbon footprint on Earth.

- Craig Technologies launched its in-orbit external experimental facility, designed to conduct electronics testing and technology demonstration at reduced cost and schedule.

- Boston University and Space Tango tested a novel flow chemistry platform to explore microgravity’s effects on chemical processes.

Establishing Reliable Access Via the “Pioneer Allocation”

As the ISS National Lab model evolves for future researchers and business cases, so too does the role of Implementation Partners—in particular CSPs. Beginning in 2012, both CASIS and NASA, via the enterprise of the ISS National Lab, have stimulated and increased investment and growth in the development of privately owned research facilities that are operating onboard the ISS. This growth in private facilities and companies that operate them has resulted in new R&D and technology capabilities for ISS users, enabled increased commercial utilization, and decreased barriers to entry for microgravity R&D.

This growth has also resulted in increased competition for ISS capacity and constrained resources (e.g., transportation, conditioned stowage, and crew time) associated with operating facilities for R&D onboard the ISS. This increased competition among the private facility owners creates obstacles that can inhibit further growth of commercial demand as well as additional private investment in ISS-dependent CSPs. This emerging bottleneck must be overcome to further attract new-to-space users, prevent the stagnation of demand, and further accelerate economic development of this segment of the LEO market. In order for private companies to continue to grow commercial utilization and thereby contribute to the national interest of developing a robust LEO economy, both CASIS and NASA recognize the need for CSPs to have at their disposal a consistent and predictable method and process for accessing a known quantity of ISS-related resources for use by their customers.

To address this important need, CASIS has created a method for identifying a sub-allocation of ISS National Lab resources for exclusive use by the CSPs and the clients they serve. This sub-allocation is titled “Pioneer Allocation” and is designed to incentivize CSP demand-generation efforts, foster an environment in which more in-space business-to-business (B2B) activity will occur, provide higher confidence levels in capital markets, support the goal of increased commercial demand and utilization, and move the U.S. toward a future state where NASA is one of many customers in a robust LEO economy.

Promoting Implementation Partner Activities, Goals, and Successes

In an effort to more frequently and effectively engage with Implementation Partners, CASIS established a new monthly meeting in FY20 focused specifically on how to bring together communications representatives from these entities to better understand how CASIS can promote Implementation Partner business goals and success. These meetings foster discussion and transparency within the ISS National Lab community and have allowed us to promote Implementation Partner news and opportunities with improved detail and accuracy.

Also in FY20, in honor of the 20th year of continuous human habitation on the ISS, CASIS encouraged Implementation Partners to share their visions for the future of living and working in space, from the perspective of the private sector. In this online essay series, several Implementation Partners discussed how the ISS has already advanced their research and validated their business models, forecasting how their companies and the LEO market overall might look 20 years from now. Read more in the online series “Visions for the Future: The Next 20 Years in Space.”

Finally, CASIS is proud to share that several ISS National Lab Implementation Partners used their skills, facilities, and knowledge to provide aid during the COVID-19 global health crisis in FY20:

- Made In Space used its facilities and resources to 3D print face shields and develop a rapid response ventilator adaptor, helping to address the critical shortage of personal protective equipment (PPE) and ventilators.

- Tec-Masters, Inc., the company that developed the original Solidification Using a Baffle in Sealed Ampoules (SUBSA) furnace for the ISS in 2002 as well as the refurbished SUBSA currently onboard the ISS, contributed much-needed PPE. Tec-Masters shifted its 3D printing efforts from the development of prototype hardware to the production of face shields to protect healthcare workers and first responders.

- Boeing, which supports the Technology in Space Prize and the Genes in Space student research competition, used one of its Dreamlifter aircraft to bring PPE to the United States from Hong Kong. Boeing helped transport 1.5 million medical-grade face masks for healthcare professionals.

- Teledyne Brown Engineering, the company that developed the Multi-User System for Earth Sensing (MUSES) Earth observation platform on the ISS, helped keep students engaged and learning during the crisis by culling through their educational materials to provide fun STEM learning activities that students can do at home.

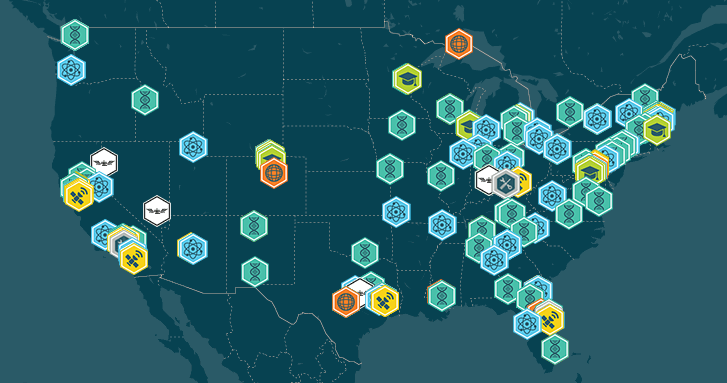

For a full list of Implementation Partners and Commercial Service Providers, see Appendices B and C.