At a Glance

- 62 newly selected projects and programs were added to the ISS National Lab portfolio in FY19, with 56% requiring no ISS National Lab funding.

- In total, 141 publications and 5 patents to date reflect results from science in space sponsored by the ISS National Lab, including FY19 publications from the Department of Defense and Novartis.

- Research in tissue chips, rodents, and crystal growth—including FY19 payloads from the National Cancer Institute, The Michael J. Fox Foundation, several major research universities, and biotechnology startup companies—continue to generate demand and produce medically relevant results.

- Projects related to materials science and in-orbit production of materials included research from Goodyear, several projects seeking to produce high-quality optical fibers in orbit, commercial and academic efforts to improve radiation monitoring devices, and healthcare-related projects in bioprinting and retinal implants.

- Research in technology development, environmental sustainability, and other areas complement these growing efforts in our newly formalized Program areas of Industrialized Biomedicine and Advanced Materials and Manufacturing.

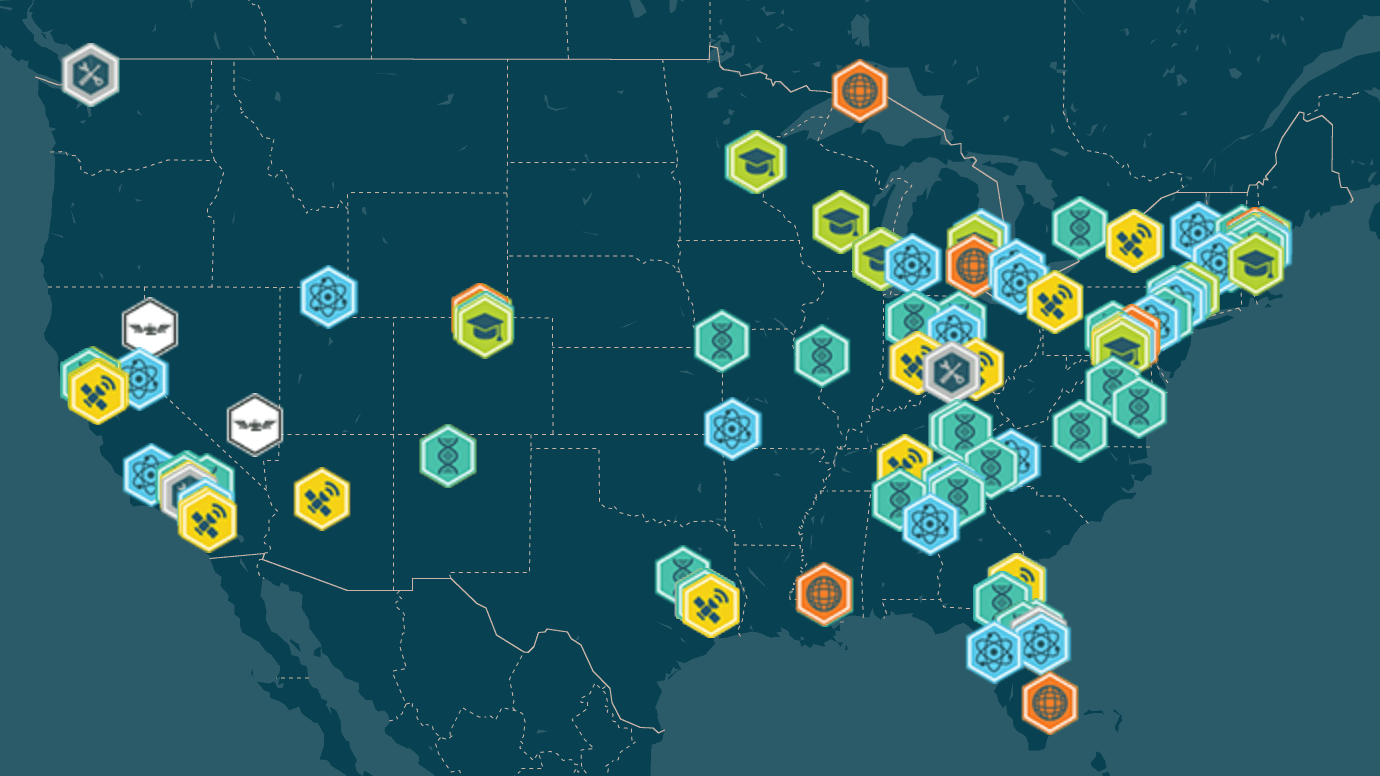

In FY19, the ISS National Lab continued progress in several R&D focus areas that have matured alongside growth of the organization and its portfolio. More than 10 ISS National Lab research solicitations were released and/or awarded in FY19, including new rolling-submission solicitations in two overarching program focus areas. Building on eight years of data from project outcomes and customer interest, including partnerships with other government agencies, the ISS National Lab continues to focus research solicitations and business development in key areas with a clear path to translational or applied outcomes that improve life on Earth and/or enable development of profitable industry in LEO. To continue to promote interest and traction in these areas, the ISS National Lab announced in FY19 that two key areas of research would receive programmatic priority over the coming year (and likely beyond). These programs are in Industrialized Biomedicine and in Advanced Materials and Manufacturing. Each of these areas has the potential to establish and strengthen the business case for space within the lifespan of the ISS, lead to meaningful acceleration of the process from basic R&D to application for several fields, and ideally achieve sustainable commercial demand for LEO (and beyond) in key sectors. The ISS National Lab began building a program-based research infrastructure in FY19 around these existing R&D portfolio segments, including the release of two related research solicitations.

Industrialized Biomedicine

Since 2012, the ISS National Lab has cultivated U.S. public and private interest in and prioritized R&D in biomedical areas with high potential to impact healthcare on Earth. In FY19, we introduced a new umbrella term, “Industrialized Biomedicine,” to describe this R&D focus area and to operationalize a Program-level approach to advancing related R&D. Industrialized Biomedicine onboard the ISS National Lab refers to flight experiments that enable biomedical advancements with a defined pathway for translation from scientific research to industrial or clinical applications, such as new therapeutics, medical procedures, or diagnostic devices.

R&D within the Industrialized Biomedicine Program includes but is not limited to:

- Translational or applied research within the medical, biotechnology, biophysics, or pharmaceutical sectors that leverages and advances known science as part of product development.

- Biotechnology design, demonstration, development, and testing with direct terrestrial applications or applications within long-term spaceflight R&D programs that support terrestrial advancements in healthcare or biomedical R&D.

- Fundamental biomedical investigations to establish clear parameters regarding the effects of microgravity within R&D areas with expected market demand for long-term spaceflight R&D programs.

In FY19, the ISS National Lab launched an Industrialized Biomedicine Request for Proposals (RFP) to further stimulate interest in this area from new-to-space investigators and experienced space researchers, particularly those interested in applied or translational research. However, R&D successes in Industrialized Biomedicine are already evident from ISS National Lab projects to date, particularly in the areas of stem cells, tissue engineering, rodent research, and macromolecular crystal growth.

For example, in the area of Industrialized Biomedicine, 141 publications and 5 patents to date reflect results from science in space sponsored by the ISS National Lab. Peer-reviewed journal articles are a critical means to disseminate findings from R&D initiatives and often lend credibility, prestige, and merit to investigators, hypotheses, and even research platforms such as the ISS National Lab. Moreover, a strong publication base often precedes commercial investment in a particular sector. Thirteen new peer-reviewed articles in FY19 formally announced preflight and postflight findings from ISS National Lab-sponsored research. Examples of FY19 peer-reviewed publications from ISS National Lab flight projects in Industrialized Biomedicine include the following:

- The U.S. Army Medical Research and Material Command (Department of Defense) described the effects of bone fracture healing, spaceflight, and the two combined in a rodent model. The results provide insight into how this system can be utilized to expedite the discovery of therapies to treat patients with fractures here on Earth.

- Novartis described how rodent muscle loss in microgravity does and does not mimic skeletal muscle atrophy on Earth. These results are important for the research community that aims to utilize the ISS as a platform to accelerate medical discovery on Earth by using space-based animal and cell models.

- Loma Linda University described spaceflight effects on young and old cardiac progenitor cells. The results demonstrate the beneficial but time-dependent difference microgravity has on these cells and uncovered pathways that might be exploited to make adult progenitor cells more regenerative, providing a potential therapeutic approach to treat people who have heart attacks.

- Genes in Space student scientists described the procedures and results from in-orbit gene expression studies. The work provides the scientific validation that genetic data can be extracted and analyzed in orbit utilizing miniPCR technology, paving the way for future in-orbit genetic research and crew health monitoring, a capability that may also further validate the ISS as a model for accelerated aging.

Additionally, one new patent granted in FY19 describes actionable results from an Industrialized Biomedicine ISS National Lab project. The patent describes the use of the persistent microgravity environment on the ISS National Lab to enhance the production of a biomedically useful compound called Pyranonigrin A, an antioxidant compound produced by some strains of the fungus Aspergillus niger. The joint patent, filed by the California Institute of Technology and the University of Southern California, resulted from an ISS National Lab project led by NASA’s Jet Propulsion Laboratory (Pasadena, CA). Secondary metabolites produced by filamentous fungi living in nature are often biologically and chemically active and sometimes have properties that make them excellent drug candidates for the treatment of human diseases. Whole genome sequencing has shown that many genes in the genomes of fungi are not expressed when fungi are grown in the laboratory, as opposed to growing in the wild, resulting in the silencing of many metabolic pathways in fungi under standard laboratory conditions. To study these cryptic metabolic pathways in fungi and unlock their potential to generate beneficial new compounds for drug discovery, scientists have long sought opportunities to expose fungi to novel environments—and in this case, space proved to be key for improving production of a medically useful compound.

For more information on success stories resulting from space-based R&D in Industrialized Biomedicine, visit Upward.

Tissue Engineering

One of the most mature sub-areas of Industrialized Biomedicine onboard the ISS is the broad field of tissue engineering and regenerative medicine, which spans from cell-based studies to organoid growth and 3D printing of human tissues. Regenerative medicine research is aimed at improving health and longevity, using tissue chips and a biofabrication facility to address larger challenges with real-world applications. Tissue engineering has many applications but often includes culturing tissues resembling those in the body to model and study human disease, allow higher-accuracy and personalized drug testing, or advance research in organ growth to address the shortage of organs for transplantation.

Tissue chips are small devices engineered to grow human cells on an artificial scaffold to model the structure and function of human tissues and organs. Because tissue chips are made using human cells and are designed to replicate facets of the physical environment cells experience inside the body, they provide higher-accuracy models. In microgravity, tissue chips have the potential to accelerate pathways for understanding the mechanisms behind disease and developing new treatments. Spaceflight induces changes in body systems that in many cases mimic the onset of health-related outcomes associated with aging and debilitating chronic human diseases on Earth. Thus, spaceflight provides opportunities both for analysis of these rapid physical changes and for testing of therapeutics in accelerated models of aging or disease.

In total, ISS National Lab activities in the area of tissue engineering and regenerative medicine have resulted in almost $30 million in grant commitments from multi-year programs with NSF and NIH, 22 peer-reviewed publications, 47 projects within the ISS National Lab R&D portfolio (supported by eight Implementation Partners), and 19 payloads flown to date (with 10 more planned for FY20). A new bioprinting facility that launched to the ISS National Lab in FY19, detailed in Section II, also showcases expanding capabilities in the area of tissue engineering.

In FY19, initial flights were completed for the first set of tissue engineering projects awarded under a partnership with the National Center for Advancing Translational Sciences (NCATS), which is part of NIH. In 2016, NCATS announced a four-year collaboration with the ISS National Lab to support the use of tissue chip technology for translational research onboard the ISS to benefit human health on Earth. The Tissue Chips in Space initiative is a multi-year, multi-flight program that aims to advance understanding of human diseases, with the goal of translating findings into potential new treatments to improve health on Earth. The collaboration has since grown to include the National Institute of Biomedical Imaging and Bioengineering (NIBIB), also part of NIH. In FY19, the second set of awards under this Sponsored Program was also announced, and workshops were held at the annual ISS R&D Conference and the annual ASGSR (American Society for Gravitational and Space Research) Conference to discuss tissue engineering and regenerative medicine in space.

The first NIH-sponsored Tissue Chips in Space awardee to fly launched on SpaceX CRS-16 in FY19. The research team from the University of California, San Francisco sought to use tissue chip technology to examine the relationship between immune aging and healing outcomes. As people age, their immune response gradually becomes impaired, resulting in a reduced ability to fight infection and disease. This process may be accelerated in microgravity, as exposure to spaceflight has been shown to lead to immune dysfunction. The research team will investigate the biology of aging by looking at immune function in microgravity and then again during the recovery of the cells after they return to Earth.

On SpaceX CRS-17 in FY19, the remaining four tissue chip investigations funded by NCATS through the first Tissue Chips in Space initiative flew to the ISS National Lab. One investigation from Emulate, Inc. is aimed at better understanding the blood-brain barrier, which could help reveal the mechanisms behind neurodegenerative diseases like Alzheimer’s. Another tissue chip investigation from the Massachusetts Institute of Technology is exploring pathways that could lead to new treatments for osteoarthritis, the most common form of arthritis, which affects millions of people. The Children’s Hospital of Philadelphia is testing tissue chip systems of the human airway and bone marrow to model how the immune and respiratory systems interact to fight infection. An experiment from the University of Washington School of Pharmacy is aimed at studying tissue chip systems that model the human kidney to gain a better understanding of proteinuria (a condition in which a person’s urine contains an abnormal level of protein), kidney stone formation, and the body’s use of Vitamin D.

The research team from the University of Washington School of Pharmacy also published an FY19 commentary in the peer-reviewed journal Clinical and Translational Science discussing the opportunities and challenges of conducting tissue chip research in space (ascpt.onlinelibrary.wiley.com/doi/full/10.1111/cts.12689). Two additional commentaries in FY19 also focused on the value of the ISS National Lab for advancing tissue chip research. In a Scientific American “Observations” article, Dr. Christopher Austin, Director of NCATS, discussed the importance of tissue chip research onboard the ISS National Lab (blogs.scientificamerican.com/observations/tiny-organs-in-orbit); and an article co-authored by ISS National Lab board member Gordana Vunjak-Novakovic published in Cell Stem Cell discussed the state of organ-on-chip technology and the value of space to possibly accelerate progress toward the technology’s use in personalized medicine (read more at www.issnationallab.org/blog/revolutionizing-medicine-with-organs-on-chips/).

The collaboration with NIH is complemented by related efforts with the NSF Engineering of Biomedical Systems Program, which has collaborated with the ISS National Lab on two joint research solicitations in the areas of cellular engineering, tissue engineering, and the modeling of physiological or pathophysiological systems that could be enhanced through sustained exposure to microgravity. The second of these solicitations was released and awarded in FY19.

Rodent Research

An additional sub-area of Industrialized Biomedicine with a strong track record for space-based success is rodent research. Scientists have used rodents as model organisms in human health studies for more than 100 years on Earth and for decades in space. Rodents are powerful models to study human disease due to their genetic similarities to humans and their short lifespans, enabling studies on accelerated timescales that have led to their extensive use in preclinical testing for new drugs. Rodent research provides accelerated models of disease for scientists to study the mechanisms behind disease and test new treatments. Space-based research using model organisms such as rodents provides insight into not only the effects of spaceflight on astronaut health but also effects that mimic human disease on Earth, such as bone loss, muscle wasting, heart disease, immune dysfunction, and other conditions. Rodent research on the ISS allows longer-term experiments in this unique environment. To date, 33 ISS National Lab rodent research projects (supported by three Implementation Partners and representing investigators from 14 U.S. states) have produced nine peer-reviewed publications—two of which are detailed earlier in this section.

In FY19, the ISS National Lab implemented a new plan to maximize science return from the high-demand, resource-intensive, and sample-size-limited rodent research program by executing “reference missions,” which adapt the standard rodent research format to maximize scientific research opportunities and resource utilization by providing multiple investigators access to biospecimens from a single mission. As part of their agreement for award of biospecimens, all investigators agree to share their data and publish their results after mission completion. In FY19, the ISS National Lab selected more than 20 projects as part of the first two Rodent Research Reference Missions, solicited via two Requests for Proposals issued in collaboration with the lab animal supplier Taconic Biosciences (which provided rodents for the mission at no cost) and the commercial Implementation Partner BioServe Space Technologies (which contributed to mission operations and biospecimen administration). Both Rodent Research Reference Missions flew in FY19. Insight gained from these missions may help advance research on diseases and aging effects involving muscle, bone, and other organ systems. For more information, visit www.issnationallab.org/blog/rethinking-rodent-research-concept-design.

Macromolecular Crystal Growth

A third sub-area with robust representation within ISS National Lab Industrialized Biomedicine R&D is macromolecular crystal growth. High-quality crystals of organic molecules, such as proteins, can lead to improvements in drug development, formulation, manufacturing, and storage as well as agricultural solutions that better protect crops and enhance plant growth. In the microgravity environment onboard the ISS, researchers are able to grow crystals that are larger and/or more well-ordered than crystals grown on Earth. Many researchers, including several from commercial entities, are already using the unique crystallization environment onboard the ISS National Lab to advance their R&D. To date, 25 ISS National Lab crystal growth projects (supported by seven Implementation Partners and representing investigators from 13 U.S. states) have produced seven peer-reviewed publications. Of note, external funding (non-NASA, non-ISS National Lab) for ISS National Lab R&D in this sub-area has increased by more than 80% over the past five years.

Example crystal growth projects that launched to the ISS in FY19 include the following.

- The National Cancer Institute (NCI) in the NIH studied how and when structural changes occur during protein crystallization to better inform cancer therapeutics and drug development.

- Frederick National Laboratory for Cancer Research (sponsored by NCI) crystallized genes associated with cancer-causing mutations to determine new approaches to prevent and treat cancers.

- Startup company MicroQuin crystallized a membrane protein found to play a key role in tumor development and survival of breast cancer cells.

- Startup company Dover Lifesciences crystallized an enzyme present in muscle and a critical enzyme for glycogen synthesis in the liver together with the enzyme glycogenin, an effort that could lead to the development of drugs to treat obesity, rare genetic disorders, and cancer.

The Michael J. Fox Foundation also launched their most recent crystal growth experiment in FY19. According to more than a decade of research, a mutation in a gene known as LRRK2 (leucine-rich repeat kinase 2) appears to be linked to Parkinson’s disease in some patients. However, despite the knowledge that this gene may be involved in some cases of the disease, researchers have been unable to unlock the full potential of this genetic research because of the difficulty in studying its gene product, the LRRK2 protein. The most recent investigation from The Michael J. Fox Foundation used a different type of flight hardware to enable larger crystal growth. Interestingly, the knowledge gained from this and related studies could also be beneficial for those who have Parkinson’s disease but do not have the LRRK2 mutation. Even when mutations in other genes may be at fault, many of the symptoms of Parkinson’s disease are the same. Thus, treatments developed using the knowledge gained from studying LRRK2 could be broadly effective for the 1 million people in the U.S., and 6 million worldwide, currently living with Parkinson’s disease. This research complements other projects in 2019 supported by the National Stem Cell Foundation and the New York Stem Cell Foundation, which are focused on studying three-dimensional models for neurodegenerative disorders using patient-derived, induced pluripotent stem cells with Parkinson’s disease and primary progressive multiple sclerosis on the ISS.

New approaches and commercial off-the-shelf hardware for space-based crystal growth continue to be developed and refined to enable expedited, repeat experiments from a growing user base. Also in FY19, an ISS National Lab investigation led by Kristofer Gonzalez-DeWhitt, consultant for The Bionetics Corporation, sought to demonstrate the feasibility of conducting protein crystal growth experiments in real time onboard the ISS. As part of the experiment, ISS crew members added solutions to the protein crystal growth hardware, observed crystal formation using a microscope onboard the ISS, and made adjustments to optimize experimental conditions in orbit. Protein crystallization experiments are usually launched to the ISS in pre-filled hardware with minimal interaction from crew members, and investigators are not able to check on the progress of the experiment or make any changes while it is in orbit.

Advanced Materials and Manufacturing

Similar to efforts in Industrialized Biomedicine, the ISS National Lab has been formally supporting R&D in the area of Advanced Materials and Manufacturing since 2012, including flight experiments within the ISS and on exposure platforms attached to its exterior. Projects within this Program area develop next-generation production methods, improve understanding of mechanisms involved in material transformations, advance fundamental materials discovery, and test processes or manufacturing methods of novel design and synthesis pathways. Previous research partners have studied combustion, complex fluid flow, interfacial phenomena, materials degradation, and in-orbit manufacturing, among others. Approximately 10% of the ISS National Lab R&D portfolio falls in this category, with more than 30 payloads launched to date in support of these projects, supported by 10 commercial Implementation Partners.

Earth’s gravity confounds precise measurements of the thermophysical properties of materials and their interactions through the effects of convection, buoyancy, sedimentation, and contact with the container in which their properties are measured. Microgravity enables research to observe, model, and exploit underlying physical mechanisms and dynamics that are typically masked by gravity-dependent phenomena in terrestrial studies of combustion, fluids, complex fluids (such as colloids and non-Newtonian fluids), soft matter, and hard materials. For example, breakthroughs in studies related to fluid dynamics, phase separation, and the fundamental internal structure of fluids may accelerate formulation chemistry; nanofluidics technologies; water and energy conservation solutions; enhanced energy generation, transfer, and storage; and development of novel materials and better manufacturing processes on Earth. Materials research in microgravity can also reveal fundamental mechanisms in crystallization, solidification, network formation, and phase transitions that are obscured in Earth’s gravity. A deeper understanding of these mechanisms, for example, contributed to the terrestrial development of improved superalloys, stabilized colloid-based products, and better casting processes. Additionally, fundamental and applied microgravity studies may have human health applications; for example, studies on interfacial phenomena promise to advance strategies for prevention of the microbial contamination of food and microbiologically influenced corrosion (or microbially induced corrosion) of materials.

In addition to microgravity, the extreme conditions of the space environment are demonstrably hostile to both materials and the components that they comprise. While Earth-based experiments are often conducted under artificial conditions to simulate extreme operational conditions, space is the ultimate test objective with simultaneous exposure to multiple environmental extremes, providing a mechanism for rapid failure mode and effect analysis.

For information on success stories resulting from space-based R&D in Advanced Materials and Manufacturing, visit Upward. Also in FY19, a joint workshop conducted by NASA’s Division of Space Life and Physical Sciences Research and Applications (SLPSRA) and the ISS National Lab connected government, university, and industry researchers and engineers interested in using microgravity and the extreme environmental conditions on the ISS to conduct innovative materials research and determining future research topics.

Advanced Materials

In 2012, the ISS National Lab issued its first solicitation in materials testing and has since released several materials science solicitations, four in collaboration with the National Science Foundation (representing $9 million in grant commitments as part of multi-year programs)—including a new FY19 joint solicitation with NSF focused on transport phenomena (e.g., research from the fluid dynamics, fire dynamics, and combustion communities). The behavior of materials in their fluid state affects the properties of the solid material (e.g., metal alloys and semiconductors used in electronic circuits, optical fibers, and solar cells). In the absence of gravity, fluid behavior is altered, enabling the development of advanced materials and better manufacturing processes for use on Earth.

With respect to ISS National Lab R&D seeking to develop or study advanced materials, 25 projects (supported by nine Implementation Partners and representing investigators from 12 U.S. states) have produced three patents and one product. In FY19, colloid research on the ISS by Procter & Gamble (P&G) resulted in a third patent relevant to product formulation and stability. Spaceflight has been a part of the P&G research portfolio for almost a decade, with experiments under NASA and ISS National Lab sponsorship studying complex fluid systems under time scales not possible on Earth. The new patent describes proposed improvements related to consumer-product functional characteristics and shelf life. These discoveries are being applied to a new formulation of a current P&G product that has more than $1 billion in annual worldwide sales.

Example advanced materials projects executed onboard the ISS National Lab in FY19 include the following.

- The Goodyear Tire and Rubber Company launched a project onboard SpaceX CRS-18 to develop advanced materials for consumer tires. Goodyear has long demonstrated innovation in space, beginning with the company’s key contributions to the lunar landing 50 years ago. Silica is a common material used in consumer tires to help enhance fuel efficiency and traction. While advances in silica technology have been made in many key areas of importance for the tire industry, silica microstructure still represents an area where research would be beneficial. The ISS National Lab investigation from Goodyear will evaluate the formation of precipitated silica particles in the functional absence of gravity onboard the ISS, where the team may be able to observe novel morphologies of silica not previously observed on Earth. Such insights could have a clear path to industrial application in the development of unique silica structures—which could result in enhanced tire performance. A breakthrough in the research of the effect of silica morphology on rubber compound properties could lead to not only significant improvements in fuel efficiency and transportation cost savings but also possibly environmental benefits to advance global efforts toward sustainable living.

- Several companies are using the SUBSA (Solidification Using a Baffle in Sealed Ampoules) hardware onboard the ISS to synthesize materials for use in radiation detection devices back on the ground. Radiation Monitoring Devices, Inc. seeks to synthesize CLYC (Cesium Lithium Yttrium Chloride) scintillator crystals for improved radiation detection devices, and Guardion Technologies aims to improve the synthesis of 2D nanomaterials for use in miniaturized ionizing radiation detectors. Additionally, the Illinois Institute of Technology examined a novel semiconductor material that is nontoxic and more affordable to produce than traditional materials. These SUBSA payloads seek to meet growing technological demands of the U.S. Department of Homeland Security and the U.S. Department of Energy. For example, CLYC scintillators could help minimize the number and types of detection devices needed for military or airport security personnel.

Additionally, an inorganic crystal growth experiment developed by the student winners of the 2018 Wisconsin Crystal Growing Competition launched to the ISS on SpaceX CRS-17. The Wisconsin Crystal Growing Competition is a free educational program available to Wisconsin students in grades 7 and higher, organized by the University of Wisconsin-Madison Chemistry Department’s Molecular Structure Laboratory. For the contest, students compete to grow the largest, highest-quality crystal on the ground. Winning students then have the opportunity to test their optimized conditions for Earth-based crystallization against crystallization in the microgravity environment of the ISS.

In-orbit Production/Manufacturing

With respect to efforts to manufacture materials in orbit, the ISS National Lab R&D portfolio includes seven projects (supported by three Implementation Partners) that have already resulted in more than 17 payloads launched to the ISS National Lab. Within this sub-area of Advanced Materials and Manufacturing, ISS National Lab funding represents less than 5% of total project costs. Commercially operated facilities currently in orbit include an additive manufacturing facility and a newly launched bioprinter (discussed in Section II).

In FY19, two new ISS National Lab investigations focused on ZBLAN optical fiber production on the ISS. These projects—one from FOMS, Inc. and one from Physical Optics Corporation—were preceded in orbit by an investigation from Made In Space, and together these represent efforts by three companies working to demonstrate in-orbit manufacturing of the optical fiber ZBLAN (for more information, see upward.issnationallab.org/the-race-to-manufacture-zblan). Optical fibers are remarkably fine glass or plastic fibers (thinner than a strand of hair) capable of transporting vast amounts of information such as light signals over great distances. There are currently three experiments sponsored by the ISS National Lab focused on the manufacture of a specific kind of optical fiber using a type of fluoride glass called ZrF4-BaF2-LaF3-AlF3-NaF, or ZBLAN. The in-orbit manufacturing promises to produce fibers with fewer imperfections, enabling lower-signal-loss optical communications for applications such as repeaterless transoceanic transmission, sensors used in the aerospace and defense industries, and improved medical devices (such as laser scalpels). FOMS (San Diego, CA), one of the companies that launched a payload in FY19, holds the first patent for technology to produce ZBLAN fibers in space.

Along with the new bioprinter, other FY19 payloads are also exploring healthcare-related applications enabled by in-orbit production. LambdaVision (Farmington, CT) is leveraging microgravity on the ISS National Lab to improve the manufacturing process for its protein-based retinal implant capable of restoring vision in patients with retinal degeneration, which affects millions of people on Earth. Currently, there is no cure for patients with the two most common types of retinal degeneration—age-related macular degeneration and retinitis pigmentosa—and treatment options are limited. LambdaVision’s retinal implant consists of multiple layers of a light-activated protein harvested from bacteria. However, when produced on Earth, gravity interferes with the uniformity of the layers. By taking the manufacturing process to the ISS, LambdaVision hopes to increase efficiency and achieve a higher-quality retinal implant by improving the uniformity and stability of the multilayer system. LambdaVision’s investigation is supported by a “Technology in Space Prize”—an award sponsored by the ISS National Lab and Boeing that supports innovative startup companies associated with the MassChallenge program, one of the leading startup accelerators. Working with commercial Implementation Partner Space Tango (Lexington, KY), LambdaVision believes the layer-by-layer approach has potential for manufacturing a number of different technologies—and that in-space manufacturing will be economically feasible.

Other R&D Focus Areas

In addition to expanding R&D in Industrialized Biomedicine and Advanced Materials and Manufacturing, the ISS National Lab continues to support R&D in other sectors and areas aligned with national priorities. For example, additional areas within which we see continued traction include technology development and demonstration (e.g., use of ISS as a testbed) and projects focused on environmental sustainability.

Technology Demonstration

The ISS National Lab serves as a destination uniquely suited to test the functionality and durability of various technologies. The microgravity environment, along with extended exposure to the harsh conditions of space, aids in demonstrating improved Technology Readiness Level (TRL) for technologies that either enable space exploration (and impact Earth by creating new opportunities for space-based R&D) or are enabled by space (benefit Earth directly). The space environment serves as a desirable destination to conduct R&D and may facilitate R&D associated with various programs designed to advance early-stage capital for technology, such as the SBIR/STTR (Small Business Innovation Research and Small Business Technology Transfer) programs.

FY19 examples of how the ISS National Lab is de-risking technology demonstration include the following.

- Hewlett Packard Enterprise’s Spaceborne Computer returned to Earth after a successful 1.5-year mission. The Spaceborne Computer represents the first long-term demonstration of supercomputing capabilities from a commercial off-the-shelf computer system on the space station. The demonstration will benefit both space-based computing as well as computer systems operating in harsh conditions on Earth. (For more information, see issnationallab.org/blog/supercomputing-in-space-hpes-spaceborne-computer-returns.)

- Startup company Orbit Fab successfully completed the first test of its Furphy tanker on the ISS, demonstrating the ability to transfer propellent between two small satellites. Furphy is a compact system for refueling satellites while in Earth’s orbit—thereby extending satellite operations. This new tanker technology has two patents pending and went from concept to flight onboard the ISS National Lab within one year. Based on this successful mission, the company raised $3 million in venture capital in the first quarter of FY20.

- SEOPS LLC’s SlingShot, a small satellite deployer system, became operational in FY19 (also less than one year from idea to launch). SlingShot enables small satellite deployment from Northrup Grumman’s Cygnus cargo vehicle. SlingShot has been used by the Department of Defense, DARPA (the Defense Advanced Research Projects Agency), NASA, and private industry customers including UbiquitiLink. As a result of their technology demonstration, UbiquitiLink has since raised $12 million toward their ultimate goal of providing satellite-based internet and cellular access for devices in areas without ground-based connectivity.

- It has been more than three years since Made In Space, with support from the ISS National Lab to de-risk test objectives, completed a demonstration mission of the first-ever in-orbit 3D printer, the Additive Manufacturing Facility (AMF). To date the AMF has produced more than 100 tools and other objects in orbit. Made In Space applied lessons learned from the AMF to their current development of multiple additive manufacturing tools anticipated for launch in the coming years, including a bioprinter, a Commercial Polymer Recycling System (CPRS), and other manufacturing platforms for use in microgravity. The CPRS aims to demonstrate plastic recycling capabilities in microgravity, and together with the AMF, will enable semi-closed-loop recycling of used broken parts and excess packaging in orbit into new parts and tools. Made In Space additionally leveraged knowledge gained from these ISS National Lab activities to secure a new FY19 $74 million NASA contract for Archinaut, a program to manufacture and assemble spacecraft components in LEO—to support space exploration and commercialization.

Environmental Sustainability

The ISS National Lab also provides an ideal platform to evaluate technologies for improvements in ecosystem and atmospheric monitoring, membrane and water purification systems, green manufacturing processes including biodegradable polymers, and agricultural processes as potential solutions for a healthier planet. Sustainability bridges all of the science verticals we support, and related projects comprise approximately 10% of our portfolio, with 31 projects supported by nine Implementation Partners. Of these projects, 60% represent private-sector R&D. A roundtable event at the annual ISS R&D Conference gathered many of these groups together to discuss possible future directions within this focus area—which has already produced four publications and five products from related ISS National Lab R&D initiatives. Three of these products, applications for complex processing tasks based on a prototype that used remote sensing data sets from ISS imaging sensors, are new in FY19.

Data generation continues to outpace processing capabilities in the era of LEO democratization. Advances in remote sensing and satellite technology mean that “big data” is making its way into the hands of the larger community. To prepare for the wealth of information that is coming with planned sensors on the ISS, in LEO, and beyond, rapid innovation in computing technology is paramount. Dr. James Goodman of HySpeed Computing developed a web application that combined commercial and open-source software layers into an enterprise system that runs in the cloud, generating results on-demand per the user’s request (for more information, see upward.issnationallab.org/constellations-clouds-the-conundrum-of-big-data-processing). Using data from the Hyperspectral Imager for the Coastal Ocean (HICO), which collected more than 10,000 images of Earth during its five years of operations onboard the ISS, Dr. Goodman showed that cloud computing could efficiently deliver the power of image analysis to a global user community. He tested his framework in a proof-of-concept product with customers of Harris Corporation, then expanded to develop several products newly for sale in FY19 through the CloudEO Store, a global marketplace for on-demand geoanalytics:

- VegetationVitality enables users to quickly produce value-added vegetation products and reports applicable to areas such as agriculture, forestry, climate change analytics, logging, and recreation planning.

- WaterExtent provides global insights on the location and quantity of water, critical for human health and welfare, food security, and environmental sustainability.

- LandMask provides a time series of land and other nonaquatic components—such as vegetation, snow, and ice—for coastal change assessment, water quality, ecosystem status or other aquatic and coastal investigations.

Also of note, as a result of their sustainability collaboration with the ISS National Lab, Target Corporation received an honorable mention in business magazine Fast Company’s 2019 World Changing Ideas Awards, which recognize businesses, policies, and nonprofit organizations that are “poised to help shift society to a more sustainable and equitable future.” The award resulted from the ISS Cotton Sustainability Challenge, sponsored by Target in partnership with the ISS National Lab in FY17, which sought to generate ideas on how the ISS could be leveraged to improve the use of natural resources such as water for sustainable cotton production on Earth.